Understanding Product Lifecycle Management in 3D Printing

Product Lifecycle Management (PLM) has emerged as a pivotal strategy in modern businesses, particularly within the rapidly evolving landscape of 3D printing. This article delineates the intricate relationships between PLM and 3D printing, emphasizing how these concepts converge to foster innovation, efficiency, and sustainable practices in various industries.

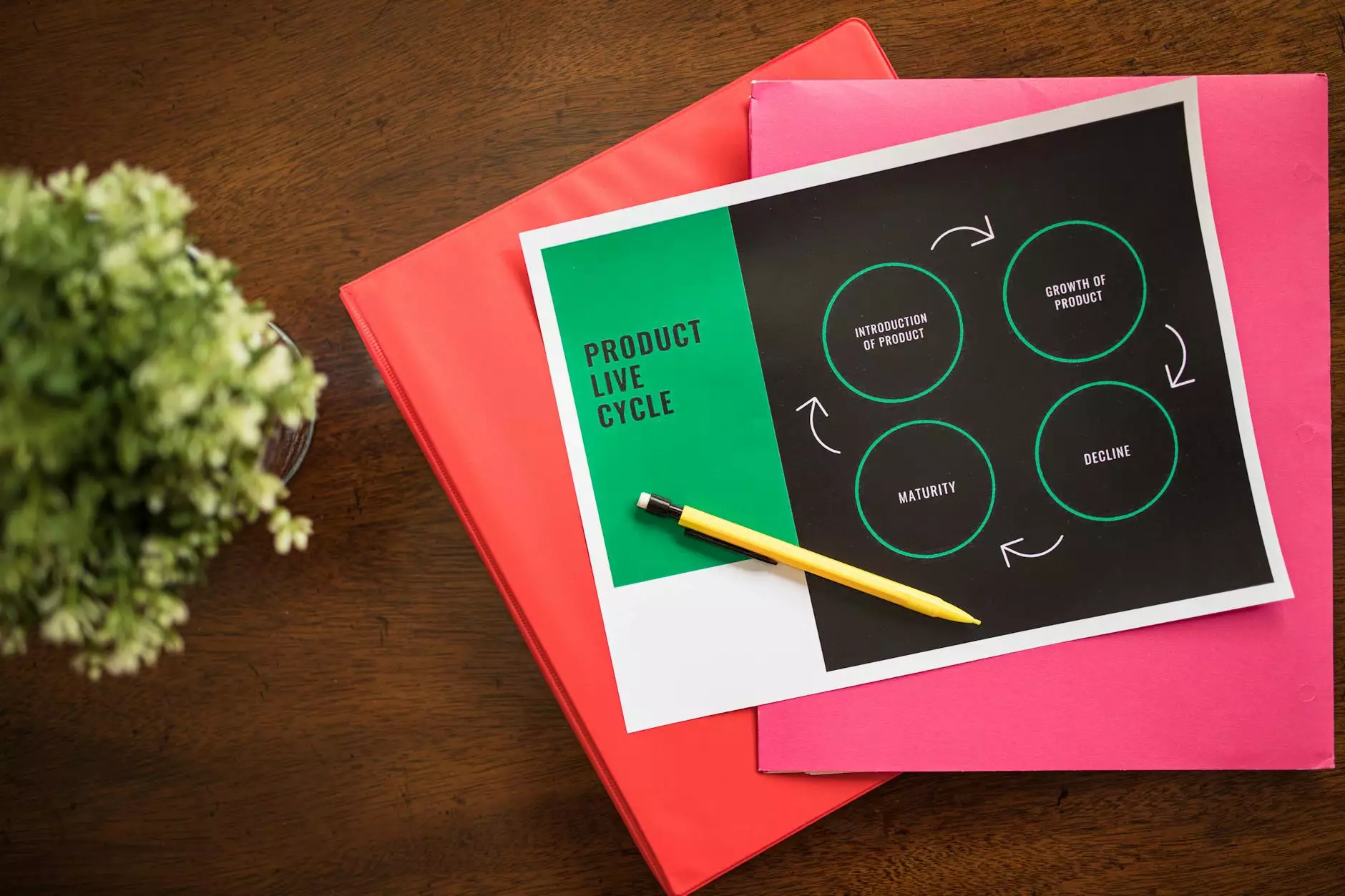

The Essence of Product Lifecycle Management

Product Lifecycle Management refers to the holistic approach of managing a product’s lifecycle stages, from ideation and design through development and manufacturing, to service and disposal. In essence, PLM integrates people, processes, and technologies to streamline these stages, ensuring that companies can maximize their products' value while minimizing costs and time-to-market.

Key Stages of Product Lifecycle Management

The stages of PLM typically include:

- Ideation: Generating new ideas and concepts.

- Design: Creating prototypes and engineering specifications.

- Manufacturing: Facilitating production processes and assembly.

- Distribution: Managing logistics and supply chain elements.

- Service: Supporting product maintenance and customer feedback.

- Disposal: Implementing sustainable end-of-life strategies.

The Intersection of 3D Printing and PLM

3D printing, or additive manufacturing, revolutionizes traditional manufacturing methods by producing parts layer by layer from digital models. This technology aligns seamlessly with product lifecycle management through its ability to enhance design flexibility, reduce waste, and facilitate rapid prototyping.

1. Accelerating the Design Phase

The design phase benefits immensely from 3D printing capabilities. Designers can create complex geometries that would be unfeasible or too costly to produce using traditional methods. Leveraging PLM tools enables teams to collaborate effectively, iterate designs quickly, and validate concepts early in the lifecycle.

2. Cost and Time Efficiency

By integrating 3D printing into their PLM strategies, businesses can significantly reduce lead times and costs. Traditional manufacturing often requires expensive tooling and lengthy setup times, whereas 3D printing minimizes these barriers, allowing for more agile and responsive production processes.

3. Enhancing Prototyping Processes

Prototyping is a critical component of product development, and 3D printing is synonymous with rapid prototyping. With the ability to quickly create functional parts and models, organizations can test and validate their designs more effectively. This rapid feedback loop is vital in refining products before entering mass production.

4. Enabling Customization

One of the most significant advantages of 3D printing is the ability to customize products for specific customer needs. By incorporating PLM strategies, businesses can track user preferences and feedback continuously, adapting their designs to meet market demands swiftly.

Implementing PLM in a 3D Printing Context

For businesses venturing into 3D printing, implementing product lifecycle management effectively is crucial. Below are steps to consider:

1. Develop a Clear PLM Strategy

A clear strategy outlines objectives, defines the roles of stakeholders, and establishes processes to integrate PLM with existing systems. This strategic plan should prioritize collaboration among cross-functional teams, including design, engineering, manufacturing, and marketing.

2. Choose the Right PLM Software

Selecting a robust PLM software tailored to the specific needs of 3D printing is essential. The software should facilitate real-time collaboration, version control, and data management to enhance efficiency throughout the product lifecycle.

3. Foster Cross-Functional Collaboration

Encourage collaborative practices among different departments. By fostering a culture of transparency and teamwork, organizations can leverage the collective knowledge and skills to optimize product development processes.

4. Invest in Training and Development

Continuously invest in training for staff to ensure they are equipped with the necessary skills to navigate PLM tools and 3D printing technologies effectively. A knowledgeable team can better exploit the benefits of integrating these methodologies.

The Benefits of Product Lifecycle Management in 3D Printing

Organizations that successfully integrate product lifecycle management into their 3D printing operations experience numerous benefits, including:

- Improved Product Quality: By maintaining rigorous controls and constant communication throughout the lifecycle, product quality significantly increases.

- Enhanced Innovation: PLM encourages collaboration, leading to innovative solutions and ideas that may not emerge in siloed environments.

- Faster Market Readiness: The capability to prototype rapidly accelerates time-to-market for new products.

- Cost Reductions: Efficiency savings from decreased waste and improved processes translate directly into reduced costs.

- Sustainability: Effective lifecycle management facilitates the strategic implementation of sustainable practices, from materials sourcing to end-of-life recycling.

Challenges in Integrating PLM and 3D Printing

Despite the myriad benefits, organizations may face challenges when integrating PLM with 3D printing. Recognizing these challenges prepares companies to confront and overcome them effectively.

1. Cultural Resistance

Implementing new systems often meets with resistance. Employees accustomed to traditional workflows may be hesitant to adopt new PLM processes and technologies. Change management tactics, including effective communication and training, can mitigate these cultural hurdles.

2. Data Management Complexity

As 3D printing increases, so does the volume of data generated in the design and manufacturing phases. Managing this data efficiently within a PLM framework can be daunting. Companies must invest in scalable data management solutions that ensure data integrity and accessibility.

3. Technology Integration

Integrating 3D printing technologies with existing PLM systems can present significant technical challenges. Organizations must choose compatible technologies and ensure their teams are adept at leveraging these systems effectively.

Conclusion: The Future of Product Lifecycle Management in 3D Printing

The fusion of product lifecycle management and 3D printing heralds a new era of efficiency and innovation across industries. As organizations increasingly recognize the value of this integration, they are moving towards a more sustainable and responsive manufacturing framework. For businesses looking to thrive in the modern marketplace, embracing PLM principles alongside cutting-edge 3D printing technology will be an essential strategy for long-term success.

At Infotron, we are committed to leading this transformation by leveraging advanced 3D printing technologies while advocating best practices in product lifecycle management. Join us on this journey towards a more innovative and efficient future.